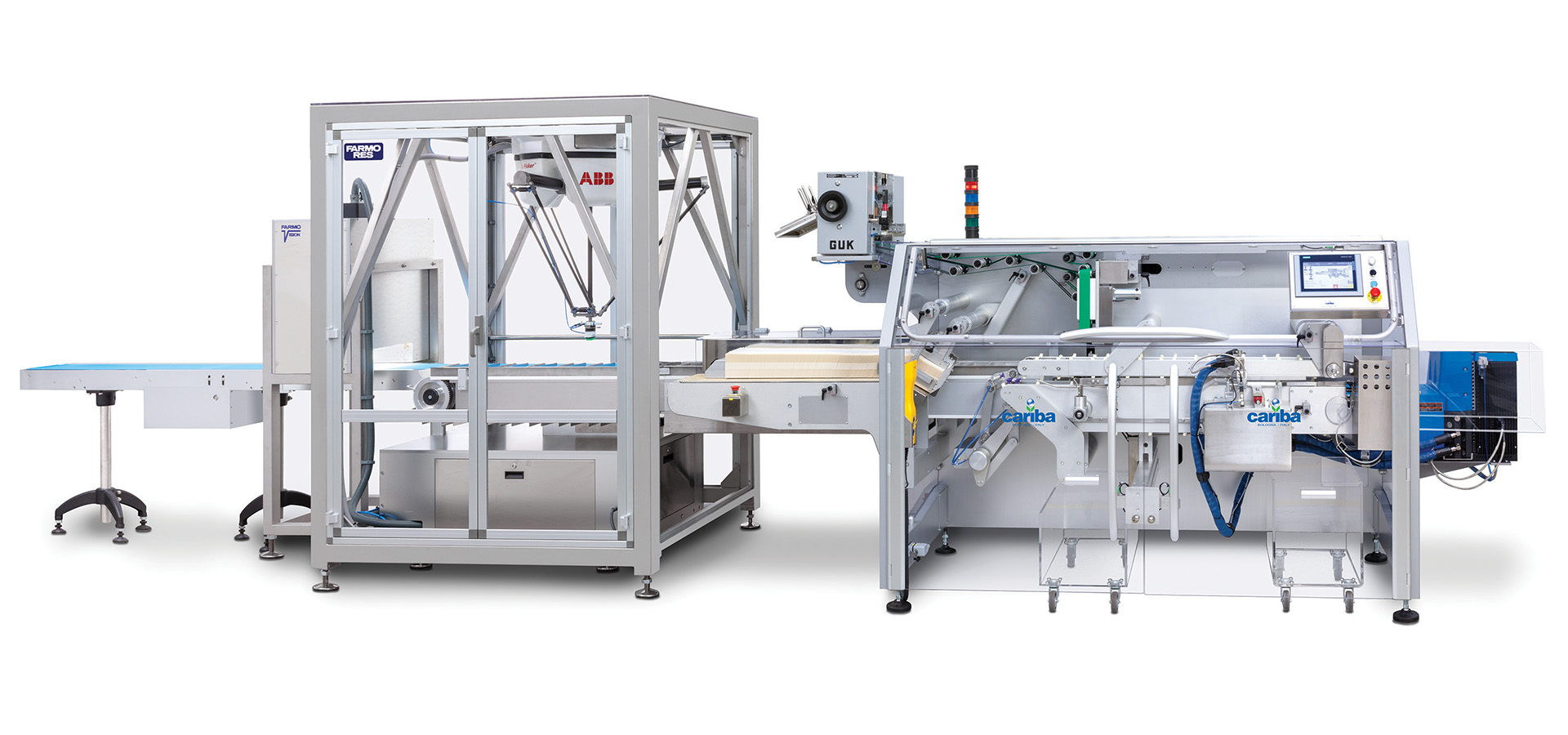

Fariba Pack offers turnkey, integrated filling and packaging lines, including Project Management and Engineering support throughout the course of the entire project. An assessment of your room layout, process flow, user requirement specifications, and packaging components allows our team to provide packaging lines designed for optimal efficiency and versatility.

As part of our successful project strategy, a Senior Service Engineer is assigned to each project and provides support from kick-off to SAT, ensuring strong service experience for our customers from project initiation into production.